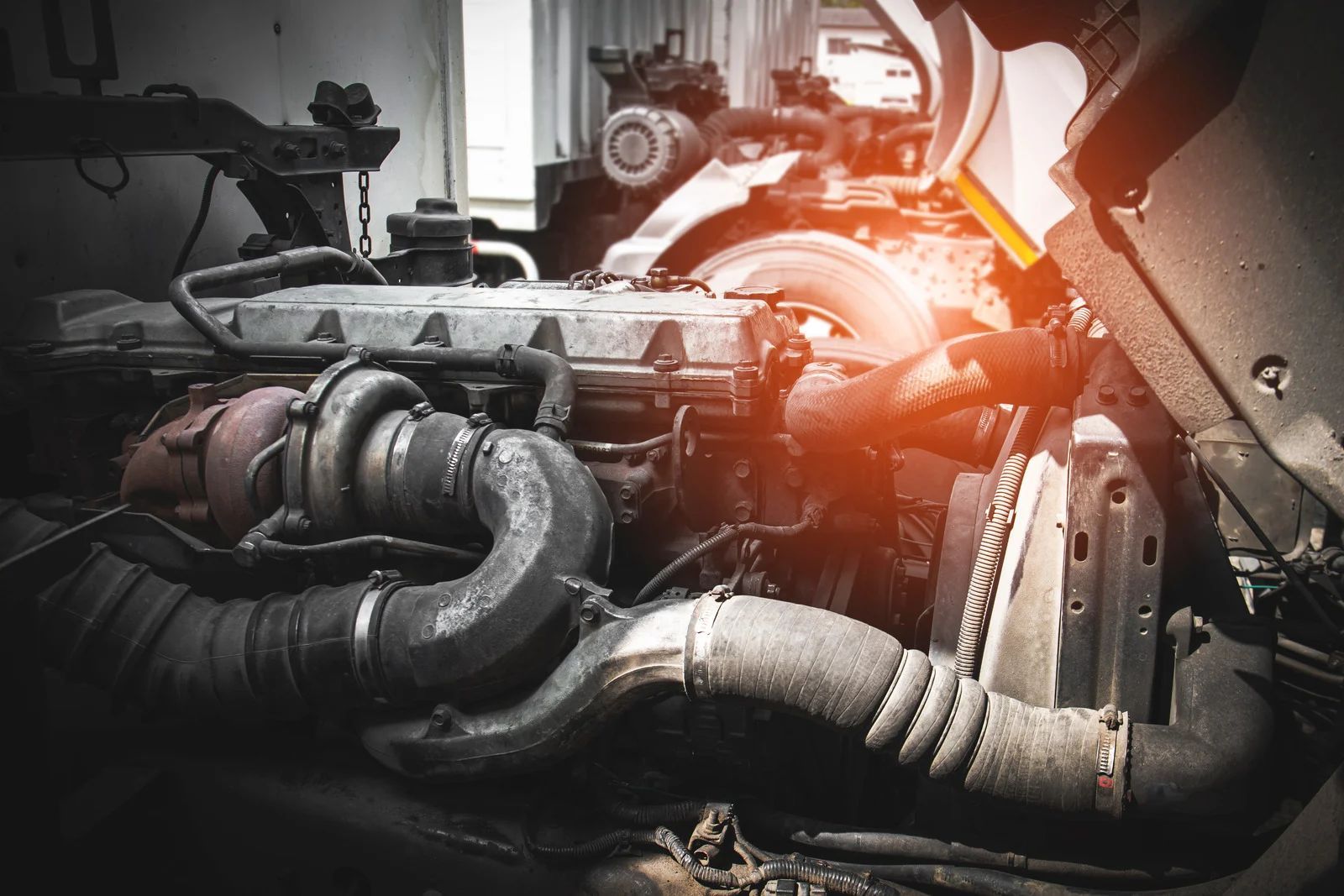

Common Diesel Engine Problems and How to Prevent Them

Diesel engines are built for endurance, but like any hardworking machine, they need proper attention to stay in top shape. Whether used in trucks, generators, or heavy equipment, diesel engines require regular upkeep to avoid costly breakdowns and downtime. Understanding the most common diesel engine problems—and what causes them—can help avoid major repairs and protect your investment.

Hard Starts and Failure to Start

A diesel engine that struggles to start or refuses to turn over usually signals an issue with compression, fuel delivery, or the glow plugs. Low compression is often linked to worn piston rings or leaky valves. Fuel delivery problems can result from clogged filters or air in the fuel lines. Dirty glow plugs or weak batteries make cold starts especially difficult. Keeping the fuel system clean, replacing filters on time, and inspecting glow plugs regularly can help prevent these frustrating starts.

Fuel Contamination

Diesel fuel contamination is one of the leading causes of engine damage. Water, dirt, and microbial growth can enter fuel tanks through poorly sealed caps or during refueling. Contaminated fuel leads to injector failure, poor performance, and in extreme cases, total engine shutdown. Using quality fuel, adding biocides if needed, and routinely draining the water separator are essential preventative steps.

Black, White, or Blue Exhaust Smoke

Unusual exhaust smoke is a telltale sign that something isn’t right. Black smoke typically indicates too much fuel or insufficient air, caused by a clogged air filter, faulty injectors, or a malfunctioning turbocharger. White smoke points to unburned fuel, often linked to timing issues or damaged injectors. Blue smoke suggests oil is burning in the combustion chamber, which may be due to worn piston rings or valve seals. Regular inspections and prompt repairs help reduce the risk of these emissions.

Overheating

Diesel engines can overheat when the cooling system isn’t functioning properly. Leaking coolant hoses, a blocked radiator, or a faulty thermostat can cause the temperature to rise quickly. Overheating damages critical engine components like the head gasket and pistons. Checking coolant levels, flushing the system periodically, and keeping an eye on temperature gauges during operation are all smart practices.

Injector Failure

Diesel fuel injectors are extremely precise and operate under high pressure. Over time, they can become clogged, leak, or fail to deliver the correct spray pattern. Poor fuel economy, engine misfires, and rough idling often point to injector problems. Using high-quality fuel, adding injector cleaner to the tank, and following service intervals can help extend the life of your injectors.

Turbocharger Troubles

A failing turbocharger can reduce engine power and performance. Oil leaks, noisy operation, or excessive smoke can signal a failing turbo. Dirt buildup or lack of lubrication usually causes these issues. Sticking to a strict oil change schedule and using the right grade of oil will help maintain turbocharger health.

Electrical and Sensor Issues

Modern diesel engines rely on a network of sensors and electronic control units. Corroded wiring, faulty sensors, or computer glitches can trigger warning lights and alter performance. Moisture and vibration are common culprits. Protecting electrical components, using dielectric grease on connections, and conducting regular diagnostics help avoid surprises.

Reliable Diesel Service You Can Count On

At The Real Deal Diesel, we’ve been solving diesel engine problems for over 15 years. Our experienced team knows what it takes to keep diesel engines running strong from fuel systems to turbochargers. Based in LaFollette, TN, we provide dependable maintenance and repair services that help prevent these common issues before they start. Reach out today and let us help you keep your diesel equipment performing at its best.