Transmission Maintenance for Diesel Trucks: What You Need to Know

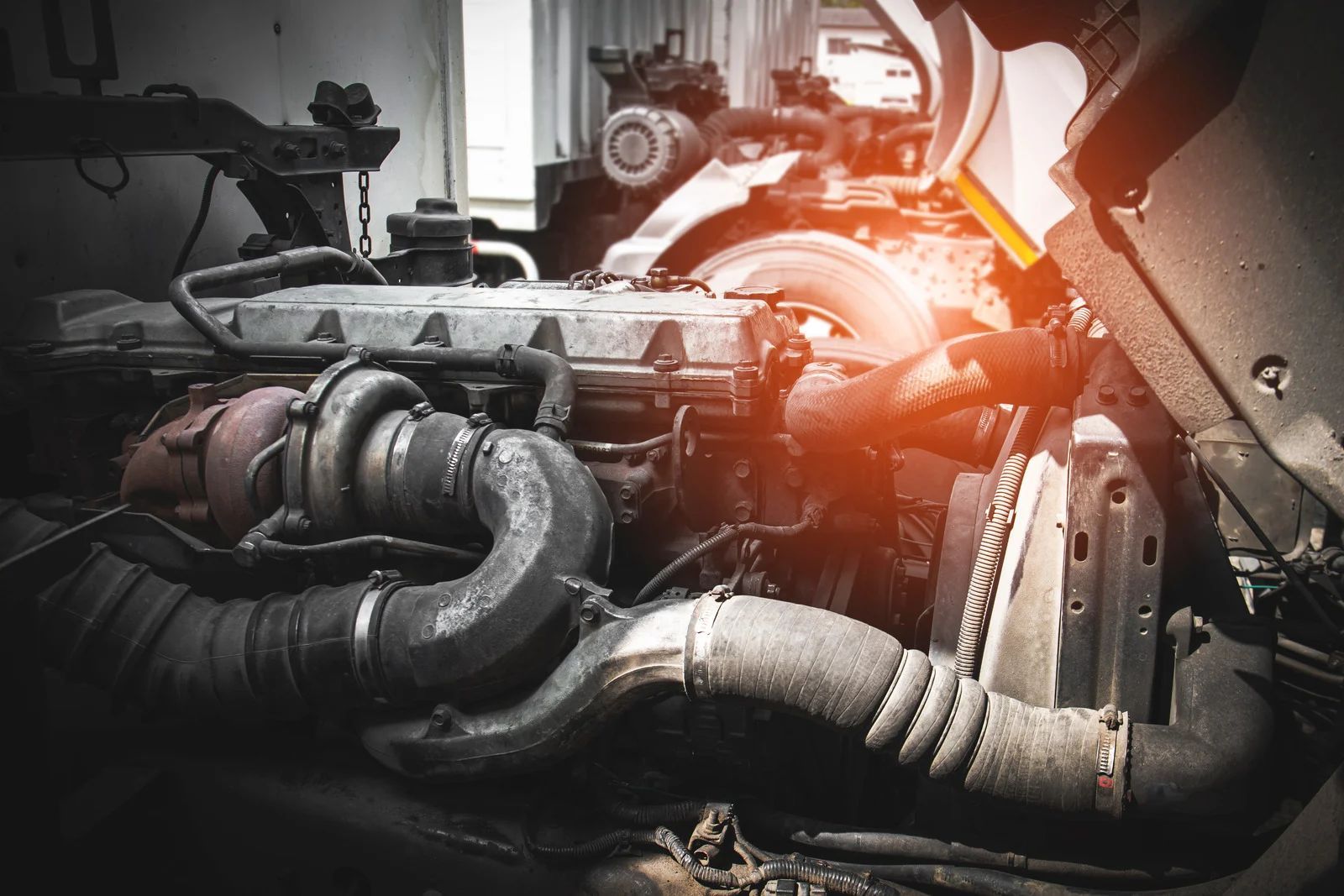

Diesel trucks are built for strength, endurance, and heavy workloads. Whether towing large trailers, carrying commercial equipment, or managing long hauls, these vehicles rely heavily on their transmission systems. Proper transmission maintenance plays a major role in ensuring your diesel truck performs efficiently and stays on the road longer without costly breakdowns.

The transmission is the powerhouse that transfers energy from the engine to the wheels. In diesel trucks, which typically carry heavier loads than gas-powered vehicles, the transmission endures even more stress. That makes regular care not only smart but essential.

Understanding the Role of Transmission Fluid

One of the most critical components in the transmission system is the fluid. It lubricates the internal parts, cools the system, and helps the gears shift smoothly. Over time, transmission fluid degrades and collects debris. When that happens, performance drops, heat builds up, and wear increases.

Replacing transmission fluid at manufacturer-recommended intervals can make a noticeable difference. For trucks used in heavy-duty or commercial applications, fluid changes may need to happen more often than standard schedules suggest. It's important to monitor the condition of the fluid—clean, reddish fluid indicates good condition, while dark or burnt-smelling fluid is a warning sign.

Filter and Pan Maintenance

Transmission filters trap debris and contaminants that can harm internal parts. If the filter becomes clogged, it can block fluid flow and strain the system. Replacing the transmission filter and cleaning the pan during service helps preserve smooth operation and extend the transmission's life.

Ignoring these steps can lead to sluggish performance, gear slipping, or even total transmission failure.

Preventative maintenance beats emergency repairs every time.

Inspecting for Leaks and Wear

Transmission leaks can be small but dangerous. Leaking fluid reduces lubrication and cooling, increasing the risk of overheating and damage. Periodically inspecting the undercarriage for puddles or drips can help catch leaks early. Damaged seals, worn gaskets, or cracked pans are common causes, and addressing them early saves time and money.

Shifting delays, odd noises, or vibrations during acceleration might point to developing issues within the system. These signs should never be ignored, and quick diagnostics can prevent more serious problems.

The Importance of Transmission Flushes

Transmission flushes remove old, dirty fluid and replace it with fresh, clean fluid. This process also clears out deposits and contaminants that regular fluid changes might leave behind. For high-mileage or work-intensive diesel trucks, flushes can help maintain strong performance, reduce wear, and prevent premature failure.

Not every truck will need a flush at the same interval. Factors such as driving conditions, load weight, and vehicle age influence the right schedule. Professional assessment is the best way to determine when a flush is necessary.

Protecting the Lifespan of Diesel Transmissions

Diesel truck transmissions aren’t cheap, and neither is downtime. Sticking to a proactive maintenance schedule is key. Small tasks like fluid checks, filter replacements, and visual inspections help prevent bigger issues. Over time, these habits save money and reduce frustrating breakdowns.

Trucks that operate in extreme heat, tow regularly, or rack up miles quickly need even more attention. Partnering with a team that specializes in diesel systems makes all the difference.

At The Real Deal Diesel, we’ve been keeping diesel trucks running strong for 15

years. Based in LaFollette, TN, our team understands the ins and outs of transmission systems and provides maintenance that keeps your truck where it belongs—on the road and working hard. If your transmission is due for service or acting up, bring it to the professionals who get the job done right.