The Importance of Preventative Maintenance for Heavy-Duty Diesel Vehicles

Heavy-duty diesel vehicles are built to handle tough jobs, long hauls, and demanding environments. But even the most rugged diesel engines require regular preventative maintenance to operate at peak performance. Skipping scheduled service leads to costly breakdowns, shortened engine life, and missed revenue. Staying ahead of problems with consistent care keeps your equipment in the field instead of in the shop.

Comprehensive Inspections Go Beyond Oil Changes

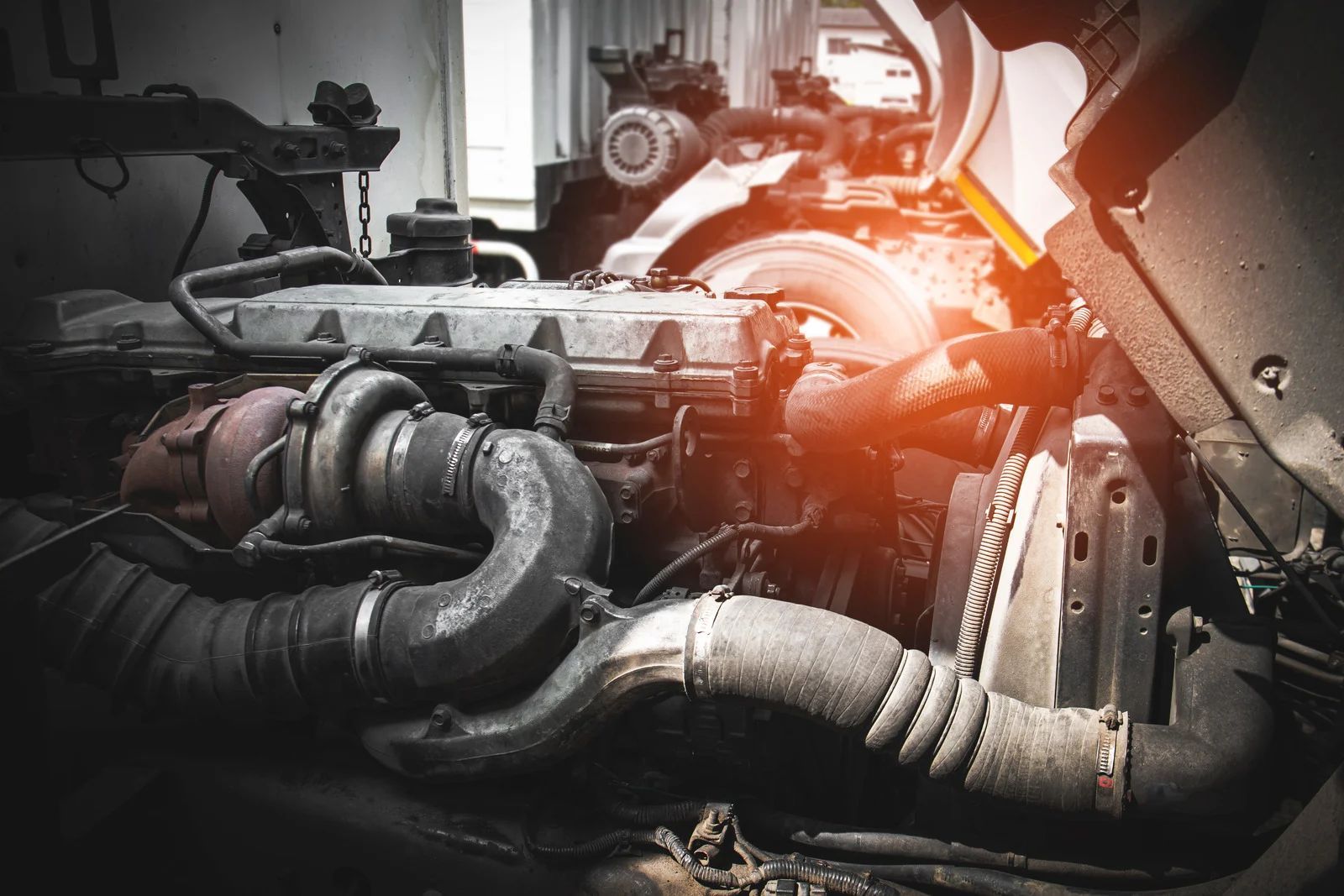

Preventive maintenance is more than just an oil change. It’s a full system check that keeps diesel engines running efficiently and safely. Technicians inspect critical components like belts, hoses, filters, brakes, batteries, and fluids. Early detection of leaks, wear, or corrosion allows for minor repairs before they turn into expensive replacements. Fluid analysis can even predict engine issues before symptoms appear, offering a major advantage over reactive repairs.

Consistent Care Extends Engine Life

Diesel engines are designed for durability, but their performance still depends on consistent care. Fuel injectors, turbochargers, emissions systems, and cooling components all operate under high stress and heat. Without regular inspection and service, these systems can develop problems that affect performance and emissions compliance. A well-maintained engine burns fuel more efficiently, extends mileage, and minimizes downtime. It also produces fewer emissions, helping you stay compliant with ever-evolving regulations.

Routine Service Prevents Costly Downtime

Unplanned repairs are disruptive and expensive. When a vehicle breaks down on the job, it leads to delays, lost income, and emergency repair costs. Maintenance services reduce these risks by identifying problems during scheduled service intervals. Whether it’s a worn belt that could snap or a low fluid level that could lead to overheating, catching the issue early avoids roadside headaches and costly tow bills.

Fuel Efficiency Improves with Regular Checks

Beyond reliability, preventative maintenance supports better fuel economy. Dirty air filters, worn injectors, or low tire pressure can all reduce efficiency and increase operating costs. With fuel prices constantly fluctuating, even small gains in mileage can lead to significant savings over time. Scheduled maintenance makes sure every part of your diesel vehicle is working together for optimal performance.

Brake and Suspension Systems Require Attention

Brake inspections, suspension checks, and alignment adjustments are also key to safety and control, especially for vehicles that carry heavy loads or travel long distances. Tires wear unevenly when alignment is off, and braking distances increase with worn pads or damaged rotors. Preventative care keeps these systems in top condition, protecting your drivers and cargo.

Electrical Systems Are Prone to Wear

Electrical systems in diesel vehicles also benefit from regular attention. Corrosion, vibration, and moisture can affect battery terminals, connectors, and wiring. Technicians check for weak connections, voltage drops, and signs of electrical strain to prevent no-start conditions or malfunctioning equipment. These inspections keep lighting, HVAC, and control systems functioning as they should.

At The Real Deal Diesel

in LaFollette, TN, we’ve spent 15

years keeping heavy-duty diesel vehicles running strong. We’ve seen firsthand how preventative maintenance saves our customers time, money, and frustration. It’s not just about checking a box—it’s about protecting your investment, avoiding downtime, and making sure your truck is ready when you are. Whether your fleet needs routine service or you're looking for a dependable team to manage your diesel maintenance, we’ve got you covered. Reach out to us today and keep your rig on the road where it belongs.